GYXTW 4 Core Fiber

GYXTW 4 Core Fiber

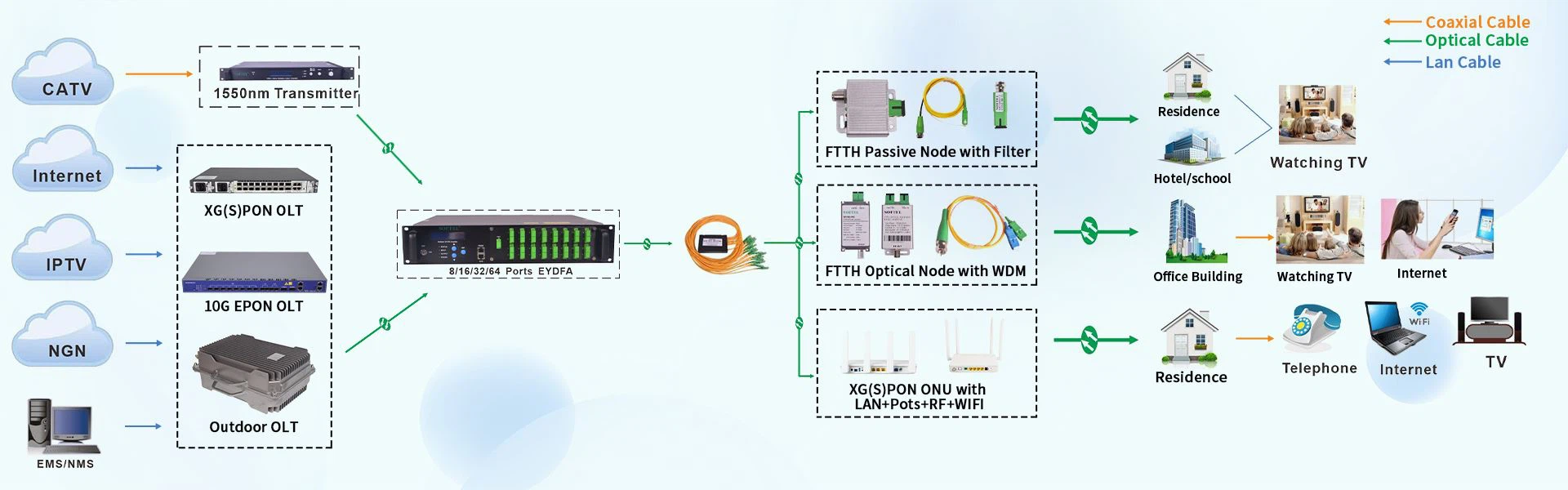

Product overview of GYXTW 4 Core Fiber

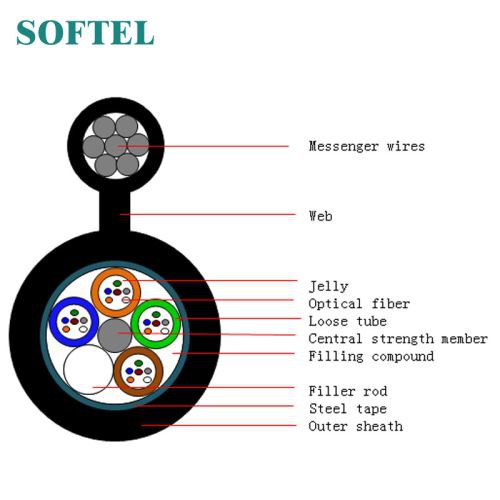

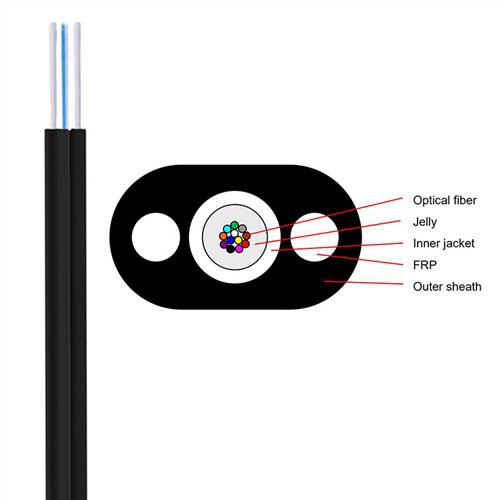

2.1 Introduction

Central tube construction, jelly compound filled, water blocking tape and steel tape, then PE outer sheath incorporated with two steel wire strength elements.

2.2 Color code

The tube color is nature. Fiber color in the tube starts from No. 1 Blue.

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

Blue | Orange | Green | Brown | Gray | White | Red | Black | Yellow | Purple | Pink | Aqua |

2.3 Cable structure and parameter

SN | Item | Unit | Value | ||

1 | No. of fibers | count | 4/6 | 8/12 | 24 |

2 | Tube diameter | count | 2.2 | 2.4 | 3.2 |

3 | Cable diameter(±5%) | mm | 8.5 | 8.7 | 9.5 |

4 | Cable weight(±10%) | kg/km | 72 | 74 | 87 |

5 | Short term tension | N | 1500 | ||

6 | Short term crush | N/100mm | 1000 |

Note: Mechanical sizes are nominal values.

3. Characteristic of GYXTW 4 Core Fiber

3.1 Min. bending radius for installation

Static: 15 x cable diameter

Dynamic: 20 x cable diameter

3.2 Application temperature range

Operation: - 40℃ ~ +60℃

Installation: -10℃ ~ +60℃

Storage/transportation: - 40℃ ~ +60℃

3.3 Main mechanical & environmental performance test

Item | Test Method | Acceptance Condition |

Tensile Strength IEC 60794-1-2-E1 | - Load: Short term tension - Length of cable: about 50m - Load time: 1min | - Fiber strain £ 0.6% - No fiber break and no sheath damage. |

Crush Test IEC 60794-1-2-E3 | - Load: Short term crush - Load time: 1min | - Loss change £ 0.1dB@1550nm - No fiber break and no sheath damage. |

4. Characteristic of GYXTW 4 Core Fiber

G652D fiber information

Mode field diameter (1310nm): 9.2mm±0.4mm

Mode field diameter (1550nm): 10.4mm±0.8mm

Cut off wavelength of cabled fiber (lcc): £1260nm

Attenuation at 1310nm: £0.36dB/km

Attenuation at 1550nm: £0.22dB/km

Bending loss at 1550nm (100 turns, 30mm radius): £0.05dB

Dispersion in the range 1288 to 1339nm: £3.5ps/ (nm•km)

Dispersion at 1550nm: £18ps/ (nm•km)

Dispersion slope at zero dispersion wavelength: £0.092ps/ (nm2•km)

Package of GYXTW 4 Core Fiber

Production process of GYXTW 4 Core Fiber

Company information

We have more than 100 staff, 10% of them are senior technicians. With more than 1,000 square meters standards production assembling lines, we have strict QC procedures. Each unit of our product will go through 3 layer QC procedures, material checking before production, stabililty and performance testing after production, packing detection before delivery.

Most of our products are exported to South America, Russia, and North European countries. Currently, Softel has its branch office in Mexico and will launch another office in Colombia, continuing supplying for numerous agents, integrated dealers, and equipment producers all over the world.

Through keen international business competition in good faith, all of our staff members feel a big accomplishment & work under heavy responsibility. In addition, we are much proud of providing our invaluable customers with our high quality, high reliability, high efficiency, and competitive products.

Hot Tags: gyxtw 4 core fiber, China, manufacturers, suppliers, factory, wholesale, Fiber Optic Cable ADSS, Outdoor ADSS Fiber Optic Cable, Self Supporting Central Tube 12 Core GYFXBY, Fiber Optic Drop Cable, Aerial Fiber Optic Cable, GYXTW 4 Core Fiber

You Might Also Like

Send Inquiry